Read Making Artisan Cheese Online

Authors: Tim Smith

Making Artisan Cheese (23 page)

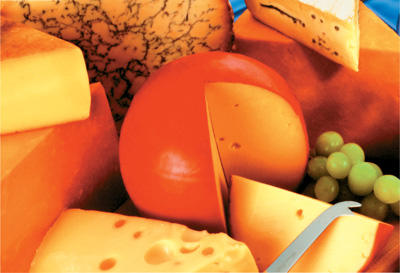

Edam’s trademark red wax coating and spherical shape make it stand out on any spread.

INGREDIENTS

2 gallons (7.6 L) low-fat milk

8 ounces (225 g) mesophilic mother culture, or ¼ teaspoon (about 2 ml) mesophilic direct-set culture

teaspoon (about 1 ml) calcium chloride diluted in ¼ cup (60 ml) cool water (see

page 72

)

1 teaspoon (5 ml) liquid rennet, or ¼ rennet tablet diluted in ¼ cup (60 ml) cool, unchlorinated water

6 cups (1.4 L) water at 175°F (79°C)

Brine solution (see

page 86

)

TECHNIQUES

For illustrated steps and tools, see Intermediate Cheese-Making Techniques,

page 82

.

PROCEDURE

Heat the milk to 90°F (32°C), then gently stir in the starter culture and cover. Let the milk ripen for ten minutes. If using homogenized milk, add the diluted calcium chloride and stir.

Maintaining the target temperature of 90°F (32°C), add the diluted rennet and stir for one minute. Cover and let set for one hour at target temperature. Check for a clean break (see

page 83

) with a curd knife (or your finger) and making one cut through the curds. Once you have a clean break, cut the curds into ½" (about 1 cm) cubes. Stir the curds gently for thirty minutes. Let the curds rest for five minutes in water bath.

Drain one-third of the whey from the cooking pot. Add 140°F (60°C) water to replace the volume of whey removed, and stir. Bring the curds to a target temperature of 98°F (37°C). Maintaining the target temperature for forty minutes, continually stir the curds to prevent them from matting. Let the curds rest for five minutes at the target temperature. Drain off the additional whey into a cooking pot using a sterilized measuring cup. Heat the whey to 125°F (52°C), and hold it at that temperature.

Pour the curds into a 2-pound (900 g) cheese cloth–lined mold. Cover the curds with one corner of the cheese cloth, and press at twenty pounds

for thirty minutes. Remove the cheese from the mold, and unwrap the cheese cloth. Set the cheese in the heated whey for thirty minutes. Remove the cheese from the whey bath, rewrap it in cheese cloth, and place it back into the mold. Press at sixty pounds for six hours. Remove the cheese from the press, and unwrap the cheese cloth. Turn the cheese, rewrap it in the cheese cloth, and press at sixty pounds for six hours. Remove the cheese from the press, and bathe it in the brine solution for three hours.

Edam as Cannon Balls?

One of the most unusual uses for Edam was as cannon balls during a naval battle between Brazil and Uruguay during the nineteenth century. Captain Coe, the commander of the Uruguayan vessel, used the load of extra-aged Edam for cannon balls when his vessel ran out of ammunition. After a few missed rounds, the cheese shattered the main mast on the Brazilian ship, and cheese shrapnel killed two sailors. A few more Edam balls tore through the ship’s sails, and the Brazilians decided to beat a hasty retreat. Kind of adds some might to the marketing phrase “Behold the power of cheese,” doesn’t it?

Remove the cheese from the brine solution, and pat dry with a paper towel. Ripen the cheese in your home cave (refrigerator) at 50°F (10°C) and 80–85 percent humidity, turning and washing the exterior daily with washing solution (using a cloth dipped in brine solution). Wax the cheese and store in your refrigerator at 50°F (10°C) and 85 percent humidity, aging for three to eight weeks.

Yield: 2 pounds (900 g)

Leiden

Leiden is a variation on Edam. Cumin was a popular spice in the Dutch city of Leiden during the fourteenth century, so it was only natural that it would find its way into the cheese. Cumin seeds draw out the moisture in the cheese as it matures, making it drier.

Follow the recipe for Edam, making the following modifications.

ADDITIONAL INGREDIENTS

1 teaspoon (about 2 g) cumin seed 1 teaspoon (about 2 g) caraway seed

PROCEDURE

Add the cumin and caraway seeds to the curds after draining.

Cabra al Vino

This recipe is based on a cheese from Murcia, Spain. It is a semisoft goat cheese that has been soaked in red wine, giving the rind a deep violet color. Sweet and smooth, it carries a distinctive flavor of both wine and cheese—a perfect combination.

This semisoft goat cheese has the rich notes and coloring of the red wine in which it is soaked.

INGREDIENTS

2 gallons (7.6 L) goat’s milk

4 tablespoons mesophilic mother culture, or ¼ teaspoon (about 2 ml) mesophilic direct-set culture

teaspoon calcium chloride diluted in ¼

cup (60 ml) cool, unchlorinated water per gallon of milk (see

page 72

)

1 teaspoon liquid rennet, or ¼ tablet dry rennet, diluted in ¼ cup (60 ml) cool, unchlorinated water

6 cups (1.5 L) water, heated to 175°F (80°C)

Red wine, enough to entirely bathe cheese, about 1.5 quarts (1.5 L)

TECHNIQUES

For illustrated steps and tools, see Intermediate Cheese-Making Techniques,

page 82

.

PROCEDURE

Heat the milk to 90°F (32°C), then gently stir in the starter culture and cover. Let the milk ripen for ten minutes. If using homogenized milk, add the diluted calcium chloride and stir. Maintaining the target temperature of 90°F (32°C), add the diluted rennet and stir for one minute. Cover and let sit for one hour at target temperature. Check for a clean break (see

page 83

) by making one cut with a curd knife (or use your finger). Once you have a clean break, cut the curds into 1/2" (about 1 cm) cubes. Stir, and let the curds rest for five minutes in water bath.

With a sterilized measuring cup, draw off one-third of the whey. Gradually add the heated water, and stir to bring the temperature of the curds to 92°F (33°C). This will take about 2 ½ cups (570 ml) of heated water. Stir continuously to keep the curds from matting at the bottom of the pot. Once you reach the target temperature, let the curds rest for ten minutes, stirring occasionally. Drain off the whey to the level of the curds using the sterilized measuring cup. Continue adding the 175°F (79°C) water, stirring constantly until the temperature of the curds reaches 100°F (38°C). Maintain the target temperature for fifteen minutes, stirring frequently to prevent the curds from matting. Let the curds sit in the pot for thirty minutes at 100°F (38°C).

Strain off the whey. Pour curds back into the pot, and mill into ¼" (6 mm) pieces. Blend in the salt.

Pour the curds into a 2-pound (900 g) cheese cloth–lined mold. Cover the curds with one corner of the cheese cloth, and press at twenty pounds for twenty minutes. Remove the cheese from the press, and slowly unwrap the cloth. Turn the cheese, rewrap it in the cloth, and press at twenty pounds for twelve hours. Repeat this process, and press again at twenty pounds for twelve hours.

Remove the cheese from the press, and bathe it in a pot containing one quart (about one liter) of red wine for twenty-four hours. Remove the cheese, and let it air-dry for six hours, or until it is dry to the touch. Repeat the wine bath.

Store the cheese in your refrigerator at 50°F (10°C) and 80–85 percent humidity for three months. Turn the cheese daily for the first two weeks. Wipe down the cheese with washing solution (a clean cloth dipped into brine solution).

Yield: 2 pounds (900 g)

Emmental

Emmental is a cheese that is as beautiful as it is tasty. Although the recipe calls for two gallons (7.6 L) of milk, you will get a bigger wheel with more holes, or “eyes,” by doubling the recipe.