The Crash Course: The Unsustainable Future of Our Economy, Energy, and Environment (31 page)

Read The Crash Course: The Unsustainable Future of Our Economy, Energy, and Environment Online

Authors: Chris Martenson

Tags: #General, #Economic Conditions, #Business & Economics, #Economics, #Development, #Forecasting, #Sustainable Development, #Economic Development, #Economic Forecasting - United States, #United States, #Sustainable Development - United States, #Economic Forecasting, #United States - Economic Conditions - 2009

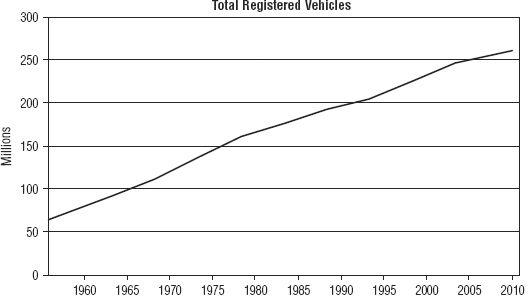

Even if we assume 100 percent recycling of the materials in a car or truck (an impossibility, as some things are lost along the way to rust or just otherwise diluted and dispersed), one thing that we can’t get around is that each year, with economic growth, there are more cars and trucks plying the global highways than the previous year (

Figure 19.4

).

Figure 19.4

Total Registered Vehicles in the United States

Source:

Research and Innovation Technology Administration Bureau of Transportation Statistics.

3

More cars and trucks mean that more of those things in the table above must be extracted from the earth. More copper, steel, aluminum, and everything else in that list must come up out of the ground to be converted into vehicles. The same is true for cell phones, computers, televisions, and everything else that includes some form of mineral wealth.

When we look at the world’s undisputed, number one consumer economy, that of the United States, a country enormously well endowed at its inception with mineral wealth, we find that it currently imports 100 percent of its needs for 18 critical, economically important elements or minerals.

1

The implication of this is clear: The U.S. economy now requires more mineral wealth than can be secured from within its own borders, and in several cases it has entirely depleted its natural endowment of mineral wealth after only 150 years of running its industrial economy.

The End of an Epoch

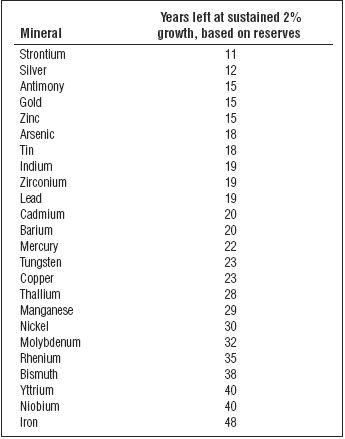

Several high-quality studies have already peered into the future of our known mineral resources and determined that some of them are now past peak and that several will be entirely exhausted within just a few decades (

Figure 19.5

).

Figure 19.5

Known Mineral Reserves and Depletion

Source:

Diederen, “Metal Minerals Scarcity and the Elements of Hope.”

4

It’s startling to realize that nearly all of these mineral resources were in fully pristine, untouched condition just 150 years ago. Where the earth once spent hundreds of millions of years concentrating these ores into a relatively few seams and pockets around the globe, humans managed to eat through a significant quantity of those in only 150 years. But that, too, underplays the situation. The amounts of minerals extracted each year have been steadily climbing through time. If we assume a 2 percent rate of increase in yearly extraction, this would mean that world extraction and use of mineral resources will double every 35 years.

And we’re continuing to increase the amounts that we extract by a fairly steady 2 percent per year, which means that in just another 35 years, we will be seeking to extract twice as much from the ground as we are today. Thirty-five years after that, we’ll want to extract four times a much. And so on, forever and ever. Or at least that’s the story as it currently stands.

Your job is simply to ask yourself if that seems either likely or doable. If, like me, your answer is,

No, this is neither likely nor doable

, then it makes sense to begin planning for a future that will be very different from today.

Reduce, Reuse, Recycle

There can be no doubt that an important tactic of the future is going be careful stewardship of our remaining resources. By reducing, reusing, and recycling our nonrenewable natural resources, we will be able to extend and blunt the day of reckoning. Unfortunately, however favorable or well-executed this strategy might be, it won’t be sufficient to prevent seismic shifts in the superstructure of our economy.

Our economy is based on a high-throughput, a somewhat disposable approach to natural resources that acts as if there were no limits to either extraction or excretion. The transition to an economy that can function on static or even diminishing supplies of certain essential raw materials is a fundamentally different economy from the one we currently have.

- The impact of the loss of materials for which no substitutes exist

. There are a variety of extremely critical rare elements for which no substitutes are known to exist for certain applications. Their loss will necessitate finding acceptable workarounds that may be less advantageous than the original—an example of technology going backward. - Materials that are combined or used in ways that prevent their easy extraction and reuse

. One of the many uses for cobalt is as an alloy material to make stainless steel. Once it is mixed in dilute amounts with steel, it would take an enormous amount of energy to recover that cobalt to use it in a different way. In fact, economically and energetically speaking, that’s really not an option; the cobalt in the steel is far too dilute, so in every practical sense, the cobalt is effectively locked into the steel. When mined potash is spread upon a field in Iowa as fertilizer, and then washes down the Mississippi River and into the Gulf of Mexico, it’s far too dilute to be recovered (although it’s plenty concentrated to support algal blooms). - Materials lost through dispersion. When steel rusts, it’s essentially lost forever

, because it’s in too dilute a form to be economically recoverable. Over time, our activities have the effect of taking relatively concentrated ores, using a lot of energy to concentrate and purify them to exceptional levels, and then carefully spreading them evenly over the surface of the earth, rendering them forever unrecoverable.

Gone with the Wind

The bottom line is that our activities tend to disperse our mineral wealth in ways that often prevent their reclamation and reuse. In many cases this is a one-way trip that isn’t amenable to recycling or reuse.

After (just) 150 years of industrialization, we can already see the end of several key mineral resources

just a few years or decades out

. And even these projections blithely assume that the energy is there to complete the task of depleting the known reserves, an assumption that I’m not willing to make.

With the depletion of certain key minerals, things will change, possibly dramatically. Am I saying that I expect the economy to come to a crashing halt if a key mineral is exhausted? No, absolutely not. But I am saying that it will no longer work the same way that it did before, and that’s what this book is about—alerting you to some seemingly quite obvious and predictable changes that are clearly headed our way.

1

Please refer to the Appendix for a list of the minerals that the United States must fully or partially import.

CHAPTER 20

Soil

Thin, Thinner, Gone

In January of 2009, an architect who’d arranged for me to speak in his community was driving me from San Francisco to an event in his hometown of Sonora, CA. As we passed through some of the most fertile farmland I had ever seen, I remarked on the bounty I could sense just outside the glass as we drove by at 65 miles per hour. Row after row, field after field, dark soil beckoning now and again from freshly turned operations spoke of the immense agricultural treasure of the place as we zoomed our way east.

Then, all of a sudden, the flat fields turned into row after row of neat, tidy houses, all squished together as if the prior 40 miles of flat expanse were irrelevant and space was suddenly hard to come by. “Hey, what’s going on here?” I asked. He briefly dipped his head and brought it up to say, “I’m embarrassed for my profession. We should, of all professions, know better than to build on farmland, but there’s no awareness yet in my colleagues of the tragedy that what you see represents.”

This silent tragedy, converting rich soils into tract housing, is happening all across the United States and elsewhere in the world and is, again, driven by financial—not necessarily thoughtful—decisions. Civilization has always grown up around and depended on the thin layer of soil that covers the earth, and we’re as dependent on it today as we’ve ever been. Without soil, food won’t grow. We would do well to remember that without primary wealth, there’s no secondary wealth, and without

that

, nothing else really matters, certainly not your stocks and bonds.

The Coming Food Challenge

In 2010, a United Nations (UN) commission reported on the state of the world’s food situation and made these statements:

. . . satisfying the expected food and feed demand will require a substantial increase of global food production of 70 percent by 2050.

Much of the natural resource base already in use worldwide shows worrying signs of degradation. Soil nutrient depletion, erosion, desertification, depletion of freshwater reserves, loss of tropical forest and biodiversity are clear indicators.

1

One-tenth of the world’s land mass is suitable for growing crops, while another four-tenths is only suitable as range land due to the thinness of the soil, steepness, dryness, or some combination of those factors. The remaining half of the world’s landmass is unsuitable for food production. The UN report examined the issue of how we will manage to feed 9.5 billion people (a 46 percent increase), given that virtually all the world’s available farmland is already under production. Increased demand is expected to require an enormous increase in crop production.

Over the past few decades, improvements in irrigation, use of fertilizers, and better crop varieties have combined to dramatically improve crop yields on a per-acre basis. But can we complacently assume that another 46 percent can be wrung out of the system over the next 40 years? What might happen if petroleum energy in the future costs too much to support the use of ever-increasing quantities of fertilizers, irrigation, and pesticides?

The Important Difference Between Soil and Dirt

Our modern, industrial agriculture system feeds more people while employing fewer people than at any time in history. Even more remarkably, crop science has delivered ever-increasing yields on a per-acre basis at ever-lower costs. As impressive as this is, you probably won’t be surprised to learn that such gains come with hidden costs. One of the most important costs has been incurred by the soil itself.

There is an important distinction between soil and dirt made here:

What is the difference between soil and dirt?

Soil is alive. Dirt is dead. A single teaspoon of soil can contain billions of microscopic bacteria, fungi, protozoa and nematodes. A handful of the same soil will contain numerous earthworms, arthropods, and other visible crawling creatures. Healthy soil is a complex community of life and actually supports the most biodiverse ecosystem on the planet.

Why is it then, that much of the food from the conventional agricultural system is grown in dirt? The plants grown in this lifeless soil are dependent on fertilizer and biocide inputs, chemicals which further destroy water quality, soil health and nutritional content.

2

In our quest to grow more food, more cheaply, on the same amount of land, year after year, we have been strip-mining the soil of its essential nutrients and qualities and converting it into lifeless dirt. What would happen if modern farming suddenly had to make do without fertilizers, pesticides/herbicides, and other petroleum inputs? Yields would fall, probably by quite a lot. Our increased yields have less to do with better technology and understanding, and more to do with the forceful application of external energy.

Industrial agriculture is marvelously cost-effective, but also remarkably brittle. It depends on a perpetual inflow of chemical fertilizers to replace the nutrients that are stripped, as well as petrochemical inputs in the form of herbicides, fungicides, and pesticides to counteract the deleterious effects of soil sterilization and monocropping.

What is the difference between Wal-Mart and an industrial farming operation? Not very much, as it turns out. Both are extremely cost-effective, and both are desperately fragile. If anything disrupts the just-in-time delivery systems around which their methods of profitability are built, either operation will experience profound difficulties. If there’s a gap in the ability to deliver shipping containers from China to Wal-Mart’s operational distribution centers, wares rapidly vanish from the shelves. It may be a cost-effective way to do things, but it’s not robust; it’s fragile.

Similarly, if an industrial farming operation is deprived of the chemical inputs required to enforce growth in their crops, yields will almost immediately suffer and plummet. Various studies of the impact of fertilization have proven that anywhere from 40 percent to 100 percent gains in grain crop yields are dependent on the application of fertilizers.

3

Sufficient supplies of fossil fuel products are essential to the success of both of these ventures.

Exporting Nutrients

The United States exports some 80 million tons of agricultural products each year (primarily grains), which represent a massive amount of water, as we’ll see in Chapter 21 (

Parched

), and vital nutrients that are harvested from the soils and shipped overseas. Without the nutrients being completely recycled back into the soils, the farmed soils quite rapidly become depleted of the vital elements that plants use to support their biological functions and growth.

One puzzle that you might have read about recently comes from the observation that plants grown and tested for their nutrient content some decades ago contained far more nutrients than plants harvested today. The quoted evidence below was assembled by Dr. Donald R. Davis and reveals the following patterns of depletion in food nutrition and soil nutrients:

- In wheat and barley, protein concentrations declined by 30 to 50 percent between the years 1938 and 1990.

- Likewise, a study of 45 corn varieties developed from 1920 to 2001, grown side by side, found that the concentrations of protein, oil and three amino acids have all declined in the newer varieties.

- Six minerals have declined by 22 to 39 percent in 14 widely grown wheat varieties developed over the past 100 years.

- Official U.S. Department of Agriculture (USDA) nutrient data shows that the calcium content of broccoli averaged 12.9 milligrams per gram of dry weight in 1950, but only 4.4 mg/g dry weight in 2003.

4

There is no mystery to these results. If you constantly harvest minerals from the soil and then truck them away without replacing them, eventually the soil will become depleted and there will be less of those minerals available to plants. In this sense, then, many farmers are in fact “mining” the soils upon which their livelihoods depend. Without closing that loop somehow and getting those nutrients back into the soils in measures equal to the rates at which they’re harvested and transported away, the practice of farming on those soils is thoroughly unsustainable. Sooner or later, those soils will become utterly sterile, suitable only for the type of farming that uses massive amounts of energy (somewhere along the line) to transport and replace those nutrients by some other means. The bidding wars that broke out in 2010 for various fertilizer companies, such as the hostile pursuit of Potash Corporation by BHP Billiton, reveal the mounting interest in securing ownership of the best remaining sources of essential (and profitable) crop nutrients.

5

The High (Energy) Cost of Low-Cost Fertilizers

The three key nutrients that are mandatory for crop growth are nitrogen (N), phosphorus (P), and potassium (K), which you’ll see listed together on the front of a bag of fertilizer as “NPK.” Virtually all of the world’s nitrogen is made using natural gas to supply the energy (and hydrogen) needed to convert gaseous nitrogen into ammonia, a form of nitrogen that’s biologically available to plants. (The gaseous form of nitrogen that makes up more than 70 percent of the atmosphere is inert and useless to plants.) It’s an enormously energy-intensive process; a pound of ammonia fertilizer requires the equivalent of a pound of diesel fuel to create it.

Therefore, any study of the extent that plant yields are dependent on nitrogen applications is really the study of the effect of fossil fuels on farming yields. As long as there are ever-increasing amounts of natural gas to dedicate to making nitrogen fertilizers, then the system we currently use should continue to function. But if this isn’t the case—if it turns out that natural gas becomes limited in some way (which indeed it someday will)—then we need to seriously think about how we’ll manage that situation.

If we lacked the energy to make nitrogen fertilizers, then plant yields would suffer enormously, until and unless we could figure out a practical way to return the harvested nitrogen back to the land in a usable form. Currently, the number one eventual destination for applied farming nitrogen is the ocean, which is where we send most of our sewage. Right now we can “afford” to do that because we have the energy to waste, but in the future it will be a sure bet that we’ll have to find ways to close the loop and return these essential nutrients to the land and the soils upon which we depend.

The story of phosphorus is even more urgent, if not alarming, as our only source for this utterly essential element is from mined rocks. Again, we “mine” phosphorus from our farming soils and send it out to the sea to become hopelessly diluted, never to be recovered. Once thought to be virtually inexhaustible, rock phosphate has been mined in ever-larger quantities over the years to support our exponential need for more food, and we can now see that a peak in this important mineral resource is plainly in view.

Our supply of mined phosphorus is running out. Many mines used to meet this growing demand are degrading, as they are increasingly forced to access deeper layers and extract a lower quality of phosphate-bearing rock (phosphate is the chemical form in which nearly all phosphorus is found). Some initial analyses from scientists with the Global Phosphorus Research Initiative estimate that there will not be sufficient phosphorus supplies from mining to meet agricultural demand within 30 to 40 years. Although more research is clearly needed, this is not a comforting time scale.

6

This is the exact same story that we’ve seen already for petroleum and other minerals. There is a fixed quantity of this vital mineral. It’s being mined in ever-larger amounts, and it’s depleting rapidly. That it will someday run out isn’t in doubt; such a fate lies in the future of any finite material that’s consumed. But “running out” isn’t really our most immediate concern; “peaking” is. If farming yields must grow to meet future demand, and those yields depend on phosphorus, then the peaking of phosphorus is going to put enormous pressures on efforts to increase yields.

Modern farming practices represent the effective mining of nutrients—a one-way trip from the soil to the sea—which we combat by mining or creating replacement nutrients elsewhere and then spreading them back on the land, using a lot of energy in the process. Right now our approach to nutrients is like a giant arrow that begins where the fertilizers are mined, passes through a farm, goes to a plate, and then out to sea.